Health

Imagine if your clothing could monitor and protect your health

Researchers Develop Programmable “Fiber Computer” for Health Monitoring in Clothing

Researchers at MIT have unveiled an autonomous, programmable computer integrated into elastic fibers that can monitor health conditions and physical activity, offering real-time alerts for potential health risks. The fiber, which is nearly invisible to the wearer, is comfortable, machine washable, and can be embedded in clothing such as shirts or leggings.

Unlike traditional “wearables” that monitor health from a single location, such as the wrist or chest, this fiber-based technology offers a unique advantage. It is woven into fabrics, allowing it to stay in contact with large areas of the body, including those close to vital organs, thus enabling a more comprehensive understanding of human physiology.

The fiber computer incorporates a range of microdevices—sensors, microcontrollers, memory, Bluetooth modules, optical communication, and a battery—into a single elastic fiber. MIT researchers attached four fiber computers to a top and a pair of leggings, with each fiber running along a limb. These computers were programmed to use machine learning to autonomously recognize different exercises, achieving an average accuracy rate of about 70%. Remarkably, when the individual fibers communicated with each other, their collective accuracy increased to nearly 95%.

Yoel Fink, Professor of Materials Science and Engineering at MIT and senior author of the study, shared his vision for the future of this technology: “Our bodies broadcast gigabytes of data through the skin every second in the form of heat, sound, biochemicals, electrical potentials, and light, all of which carry information about our activities, emotions, and health. Unfortunately, most if not all of it gets absorbed and then lost in the clothes we wear. Wouldn’t it be great if we could teach clothes to capture, analyze, store, and communicate this important information in the form of valuable health and activity insights?”

In a real-world test, U.S. Army and Navy service members will wear fiber-computer-equipped base layer shirts during a month-long winter mission to the Arctic. The mission, dubbed Musk Ox II, will cover 1,000 kilometers in temperatures averaging -40°F. These fiber computers will provide valuable health data, helping to ensure the safety of participants in extreme conditions.

“In the not-too-distant future, fiber computers will allow us to run apps and get valuable health care and safety services from simple everyday apparel,” said Fink. “We are excited to see glimpses of this future in the upcoming Arctic mission through our partners in the U.S. Army, Navy, and DARPA.”

This research builds upon more than a decade of work at MIT’s Fibers@MIT lab and was supported by various military and academic institutions. The breakthrough comes from overcoming a major engineering challenge: integrating complex microdevices into a fiber that retains flexibility and durability. The researchers achieved this by using a flexible circuit board design and an advanced thermoplastic elastomer that allows the fibers to stretch more than 60% without breaking.

The fiber computers, which can communicate via Bluetooth to a smartphone or other devices, enable the creation of a textile network within garments. When multiple fibers are embedded in a garment, they form a network that shares data and enhances functionality, as seen in their exercise-recognition model. This breakthrough could revolutionize health monitoring and injury prevention.

As the team looks ahead, their next steps include enhancing the interposer technique to incorporate additional microelectronic devices. The team is also preparing for the Arctic mission, where the fibers will be used to monitor the physiological effects of extreme cold on the human body.

U.S. Army Major Hefner, who will lead the Musk Ox II mission, highlighted the potential of this technology: “One of my main concerns is how to keep my team safe from debilitating cold weather injuries—something conventional systems just don’t provide. These computing fabrics will help us understand the body’s response to extreme cold and ultimately predict and prevent injury.”

Karl Friedl, Senior Research Scientist at the U.S. Army, emphasized the transformative potential of the technology: “Imagine near-term fiber computers in fabrics and apparel that sense and respond to the environment and to the physiological status of the individual, increasing comfort and performance while providing real-time health monitoring and protection.”

Health

Researchers Unveil 50-Cent DNA Sensors That Could Revolutionize Disease Diagnosis

The innovation lies in a low-cost electrochemical sensor stabilized with a polymer coating, which allows the device to be stored for months at high temperatures and used far from traditional lab settings

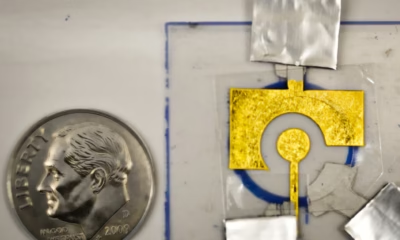

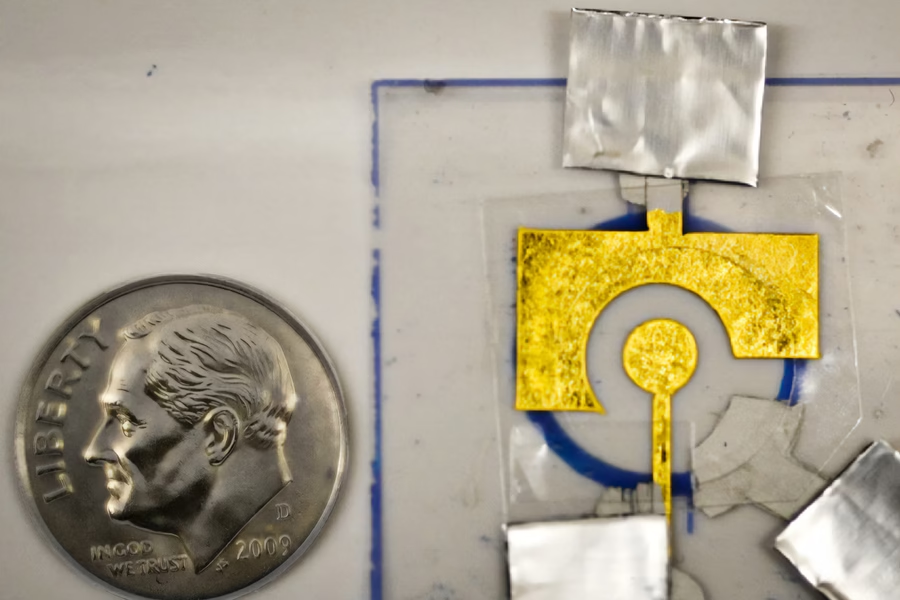

In a breakthrough that could make life-saving diagnostics accessible to millions, MIT researchers have developed a disposable, DNA-coated sensor capable of detecting diseases like cancer, HIV, and influenza — all for just 50 cents. The innovation lies in a low-cost electrochemical sensor stabilized with a polymer coating, which allows the device to be stored for months at high temperatures and used far from traditional lab settings.

At the heart of this sensor is a CRISPR-based enzyme system. When the sensor detects a target disease gene, the enzyme — acting like a molecular lawnmower — begins to shred DNA on the electrode, disrupting the electric signal and indicating a positive result.

“Our focus is on diagnostics that many people have limited access to, and our goal is to create a point-of-use sensor,” said Ariel Furst, MIT chemical engineering professor and senior author of the study, in a media statement. “People wouldn’t even need to be in a clinic to use it. You could do it at home.”

Previously, such sensors faced a major hurdle: the DNA coating degraded rapidly, requiring immediate use and refrigerated storage. Furst’s team overcame this by using polyvinyl alcohol (PVA) — a cheap and widely available polymer — to form a protective film over the DNA, significantly extending shelf life.

The sensors were tested to successfully detect PCA3, a prostate cancer biomarker found in urine, even after two months of storage at 150°F. The technology builds on Furst’s earlier work that enabled detection of HIV and HPV genetic material using similar CRISPR-based methods.

“This is the same core technology used in glucose meters, but adapted with programmable DNA,” said lead author Xingcheng Zhou, an MIT graduate student. “It’s inexpensive, portable, and extremely versatile.”

The team now aims to expand testing for other infectious and emerging diseases. They’ve been accepted into MIT’s delta v venture accelerator, signaling commercial interest and real-world application potential. The ability to ship sensors without refrigeration could be transformative for low-resource and remote settings.

“Our limitation before was that we had to make the sensors on site,” added Furst. “Now that we can protect them, we can ship them. That allows us to access a lot more rugged or non-ideal environments for testing.”

With further development, these pocket-sized DNA sensors could redefine early disease detection — from rural clinics to living rooms.

Health

Teak Leaf Extract Emerges as Eco-Friendly Shield Against Harmful Laser Rays

Raman Research Institute scientists unlock sustainable alternative for laser safety in line with green tech goals

In a significant step toward sustainable photonic technologies, scientists from the Raman Research Institute (RRI), an autonomous institute under the Department of Science and Technology (DST), Government of India, have discovered that teak leaf extract can serve as an effective, natural shield against harmful laser radiation. This breakthrough offers new potential for protecting both sensitive optical sensors and human eyes from high-intensity lasers used in medical, industrial, and defense applications.

The team has found that the otherwise discarded leaves of the teak tree (Tectona grandis L.f) are rich in anthocyanins, natural pigments responsible for their reddish-brown colour. When exposed to light, these pigments exhibit nonlinear optical (NLO) properties, allowing them to absorb intense laser beams—a key feature required for laser safety gear.

The discovery, recently published in the Journal of Photochemistry and Photobiology A: Chemistry, proposes a non-toxic, biodegradable, and cost-effective alternative to conventional synthetic materials like graphene and metal nanoparticles, which are often expensive and environmentally hazardous.

“Teak leaves are a rich source of natural pigments such as anthocyanin… We explored the potential of teak leaf extract as an eco-friendly alternative to synthetic dyes in the field of nonlinear optics,” said Beryl C, DST Women Scientist at RRI, in a media statement issued by the government.

To extract this natural dye, researchers dried and powdered teak leaves, soaked them in solvents, and processed the mixture using ultrasonication and centrifugation. The resulting reddish-brown liquid was then tested with green laser beams under continuous and pulsed conditions.

Using advanced techniques like Z-scan and Spatial Self-Phase Modulation (SSPM), the dye demonstrated reverse saturable absorption (RSA)—a rare and desirable trait where the material absorbs more light as the intensity increases, effectively acting as a self-regulating shield against laser exposure.

This development is particularly crucial as laser technologies become increasingly prevalent in everyday environments—from surgical devices and industrial cutters to military-grade systems. By offering a natural and renewable solution to a global safety challenge, the RRI team has opened the door to a future of eco-conscious optical safety equipment, such as laser-resistant eyewear, coatings, and sensor shields.

Researchers also indicated that further studies will focus on enhancing the stability and commercial usability of the dye for long-term deployment.

This innovation aligns with the principles of Industry 5.0, emphasizing human-centered and environmentally responsible technology, and showcases how indigenous, sustainable resources can play a pivotal role in global tech solutions.

Health

PUPS – the AI tool that can predict where exactly proteins are in human cells

Dubbed, the Prediction of Unseen Proteins’ Subcellular Localization (or PUPS), the AI tool can account for the effects of protein mutations and cellular stress—key factors in disease progression.

Researchers from MIT, Harvard University, and the Broad Institute have unveiled a groundbreaking artificial intelligence tool that can accurately predict where proteins are located within any human cell, even if both the protein and cell line have never been studied before. The method – Prediction of Unseen Proteins’ Subcellular Localization (or PUPS) – marks a major advancement in biological research and could significantly streamline disease diagnosis and drug discovery.

Protein localization—the precise location of a protein within a cell—is key to understanding its function. Misplaced proteins are known to contribute to diseases like Alzheimer’s, cystic fibrosis, and cancer. However, identifying protein locations manually is expensive and slow, particularly given the vast number of proteins in a single cell.

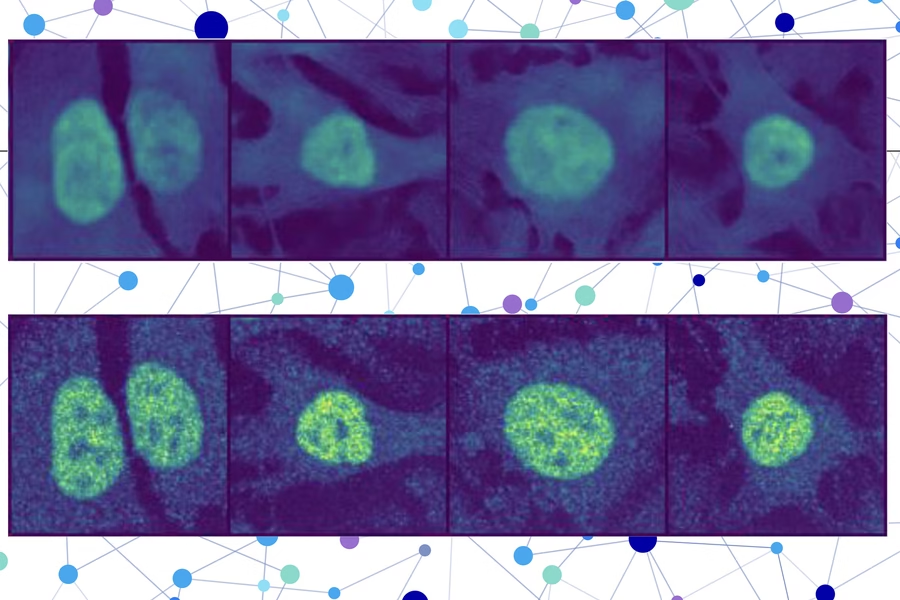

The new technique leverages a protein language model and a sophisticated computer vision system. It produces a detailed image that highlights where the protein is likely to be located at the single-cell level, offering far more precise insights than many existing models, which average results across all cells of a given type.

“You could do these protein-localization experiments on a computer without having to touch any lab bench, hopefully saving yourself months of effort. While you would still need to verify the prediction, this technique could act like an initial screening of what to test for experimentally,” said Yitong Tseo, a graduate student in MIT’s Computational and Systems Biology program and co-lead author of the study, in a media statement.

Tseo’s co-lead author, Xinyi Zhang, emphasized the model’s ability to generalize: “Most other methods usually require you to have a stain of the protein first, so you’ve already seen it in your training data. Our approach is unique in that it can generalize across proteins and cell lines at the same time,” she said in a media statement.

PUPS was validated through laboratory experiments and shown to outperform baseline AI methods in predicting protein locations with greater accuracy. The tool is also capable of accounting for the effects of protein mutations and cellular stress—key factors in disease progression.

Published in Nature Methods, the research was led by senior authors Fei Chen of Harvard and the Broad Institute, and Caroline Uhler, the Andrew and Erna Viterbi Professor at MIT. Future goals include enabling PUPS to analyze protein interactions and make predictions in live human tissue rather than cultured cells.

-

Society4 months ago

Society4 months agoStarliner crew challenge rhetoric, says they were never “stranded”

-

Space & Physics3 months ago

Space & Physics3 months agoCould dark energy be a trick played by time?

-

Earth4 months ago

Earth4 months agoHow IIT Kanpur is Paving the Way for a Solar-Powered Future in India’s Energy Transition

-

Space & Physics3 months ago

Space & Physics3 months agoSunita Williams aged less in space due to time dilation

-

Learning & Teaching5 months ago

Learning & Teaching5 months agoCanine Cognitive Abilities: Memory, Intelligence, and Human Interaction

-

Earth3 months ago

Earth3 months ago122 Forests, 3.2 Million Trees: How One Man Built the World’s Largest Miyawaki Forest

-

Women In Science3 months ago

Women In Science3 months agoNeena Gupta: Shaping the Future of Algebraic Geometry

-

Society5 months ago

Society5 months agoSustainable Farming: The Microgreens Model from Kerala, South India