Space & Physics

Fusion Energy: The quest for unlimited power

The potential benefits of fusion energy are enormous. It could provide a nearly limitless supply of energy, reduce our reliance on fossil fuels, and help combat climate change

Imagine a world with a virtually unlimited source of clean energy that could power our cities, industries, and homes without the harmful emissions and environmental impacts of fossil fuels. This isn’t science fiction—it’s the promise of fusion energy. But what exactly is fusion energy, and how close are we to making it a reality?

Nuclear fusion involves combining light elements, such as hydrogen, to form heavier elements, releasing a significant burst of energy in the process. This process, which powers the heat and light of the Sun and other stars, is praised for its potential as a sustainable, low-carbon energy source.

This process contrasts with the nuclear fission process used in nuclear power plants, where heavy atomic nuclei are split into lighter ones. But this is fraught with radioactive waste and safety concerns.

The road to practical fusion energy is steep and fraught with challenges. The foremost obstacle is achieving and maintaining the extremely high temperatures and pressures required for fusion. Similar to those at the Sun’s core, these conditions are necessary to overcome the electrostatic forces that repel the positively charged atomic nuclei. For decades, scientists have experimented with different methods to achieve these conditions. The two primary approaches are magnetic confinement and inertial confinement.

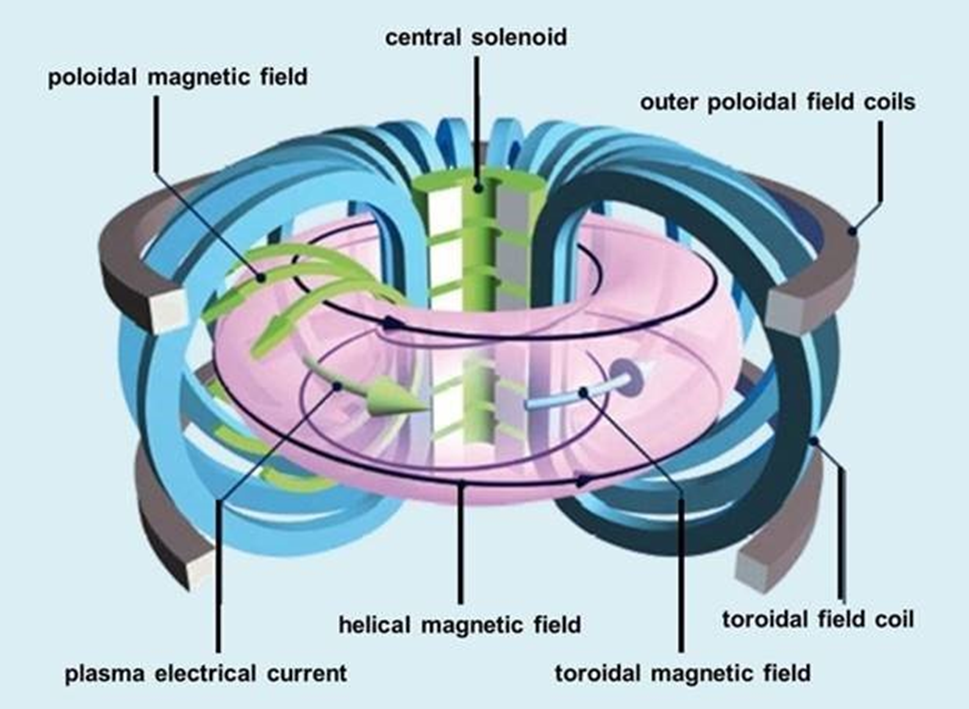

Magnetic confinement, as seen in the tokamak design, employs powerful magnetic fields to contain hot plasma within a doughnut-shaped chamber. Inertial confinement, on the other hand, involves compressing a small pellet of fusion fuel with intense laser beams to achieve the conditions for fusion. Both methods have seen significant advancements but are yet to reach the break-even point, where the energy output from fusion equals the energy input required to sustain the reaction. However, recent breakthroughs have brought us closer than ever to this elusive goal.

The primary fuel for nuclear fusion is deuterium and tritium. Deuterium and tritium are isotopes of hydrogen, the universe’s most abundant element. Isotopes are members of a family of elements that all have the same number of protons but different numbers of neutrons. While all isotopes of hydrogen have one proton, deuterium has one neutron, and tritium has two, so their ion masses are heavier than those of protium, the isotope of hydrogen with no neutrons. Deuterium can be extracted from seawater, while tritium can be bred from lithium. When deuterium and tritium fuse, they form a helium atom, which has two protons and two neutrons, and release an energetic neutron. These energetic neutrons could serve as the foundation for generating energy in future fusion power plants.

Power plants today generate electricity using fossil fuels, nuclear fission, or renewable sources like wind or water. Regardless of the energy source, these plants convert mechanical power, such as the rotation of a turbine, into electrical power. In a coal-fired steam station, coal combustion turns water into steam, which then drives turbine generators to produce electricity.

The tokamak is an experimental machine designed to harness fusion energy. Inside a tokamak, the energy produced through atomic fusion is absorbed as heat by the vessel’s walls. Similar to conventional power plants, a fusion power plant will use this heat to produce steam, which then generates electricity via turbines and generators.

The international ITER project in France is the largest and most ambitious tokamak experiment to date. ITER aims to demonstrate the feasibility of fusion as a large-scale and carbon-free source of energy

At the core of a tokamak is a doughnut-shaped vacuum chamber. Under extreme heat and pressure inside this chamber, gaseous hydrogen fuel becomes plasma, creating an environment where hydrogen atoms can fuse and release energy. The plasma’s charged particles are controlled and shaped by large magnetic coils surrounding the vessel. This property allows physicists to confine the hot plasma away from the vessel walls. The term “tokamak” is derived from a Russian acronym for “toroidal chamber with magnetic coils.”

Fusion energy scientists consider tokamaks to be the leading plasma confinement design for future fusion power plants. In a tokamak, magnetic field coils confine plasma particles, enabling the plasma to reach the conditions necessary for fusion.

The international ITER project in France is the largest and most ambitious tokamak experiment to date. ITER aims to demonstrate the feasibility of fusion as a large-scale and carbon-free source of energy. It’s a collaboration involving 35 countries, including India, and is expected to produce first plasma in the coming years.

The primary objective of ITER is to investigate and demonstrate burning plasmas—plasmas where the energy from helium nuclei produced by fusion reactions is sufficient to maintain the plasma’s temperature, reducing or eliminating the need for external heating. ITER will also test the feasibility and integration of essential fusion reactor technologies, such as superconducting magnets, remote maintenance, and systems for exhausting power from the plasma. Additionally, it will validate tritium breeding module concepts that could enable tritium self-sufficiency in future reactors.

ITER made headlines just last year when it achieved a major milestone: the successful installation of its first-of-a-kind superconducting magnet system. This system is crucial for creating the powerful magnetic fields needed to contain the superheated plasma. This achievement brings us one step closer to achieving sustained fusion reactions.

On October 3, 2023, the Joint European Torus (JET) project in Oxford produced power for five seconds, resulting in a “ground-breaking record” of 69 megajoules of power. That energy was generated using only 0.2 milligrams of fuel.

An alternative method is inertial confinement fusion, where a compact fusion fuel pellet is compressed by high-powered lasers. The National Ignition Facility (NIF) in the United States is leading the way in this research. On December 5, 2022, the National Ignition Facility (NIF), located at the Lawrence Livermore National Laboratory in California, directed a series of lasers to emit 2.05 megajoules of energy towards a small cylinder containing a frozen pellet of deuterium and tritium, which are denser variants of hydrogen. The pellet underwent compression, resulting in the generation of temperatures and pressures of sufficient magnitude to induce fusion of the hydrogen contained inside it. During an extremely brief ignition, the merging atomic nuclei discharged 3.15 megajoules of energy, surpassing the amount of energy necessary to heat the pellet by approximately 50 percent. This stage is crucial in the journey towards the practical realisation of fusion energy production.

On October 3, 2023, the Joint European Torus (JET) project in Oxford produced power for five seconds, resulting in a “ground-breaking record” of 69 megajoules of power. That energy was generated using only 0.2 milligrams of fuel. In addition, many private companies are making waves in the fusion energy scene.

While these achievements are remarkable, there are still many technical hurdles to overcome. We need to improve the efficiency and durability of fusion reactors, develop materials that can withstand the extreme conditions inside them, and create systems for safely handling and breeding tritium.

Despite these challenges, the potential benefits of fusion energy are enormous. It could provide a nearly limitless supply of energy, reduce our reliance on fossil fuels, and help combat climate change. Imagine a world where energy is abundant, clean, and available to all—fusion energy could make this vision a reality. As we look to the future, the quest for fusion energy represents one of the greatest scientific and engineering challenges of our time. It’s a testament to human ingenuity and our unwavering determination to solve the world’s most pressing problems.

Space & Physics

MIT unveils an ultra-efficient 5G receiver that may supercharge future smart devices

A key innovation lies in the chip’s clever use of a phenomenon called the Miller effect, which allows small capacitors to perform like larger ones

A team of MIT researchers has developed a groundbreaking wireless receiver that could transform the future of Internet of Things (IoT) devices by dramatically improving energy efficiency and resilience to signal interference.

Designed for use in compact, battery-powered smart gadgets—like health monitors, environmental sensors, and industrial trackers—the new chip consumes less than a milliwatt of power and is roughly 30 times more resistant to certain types of interference than conventional receivers.

“This receiver could help expand the capabilities of IoT gadgets,” said Soroush Araei, an electrical engineering graduate student at MIT and lead author of the study, in a media statement. “Devices could become smaller, last longer on a battery, and work more reliably in crowded wireless environments like factory floors or smart cities.”

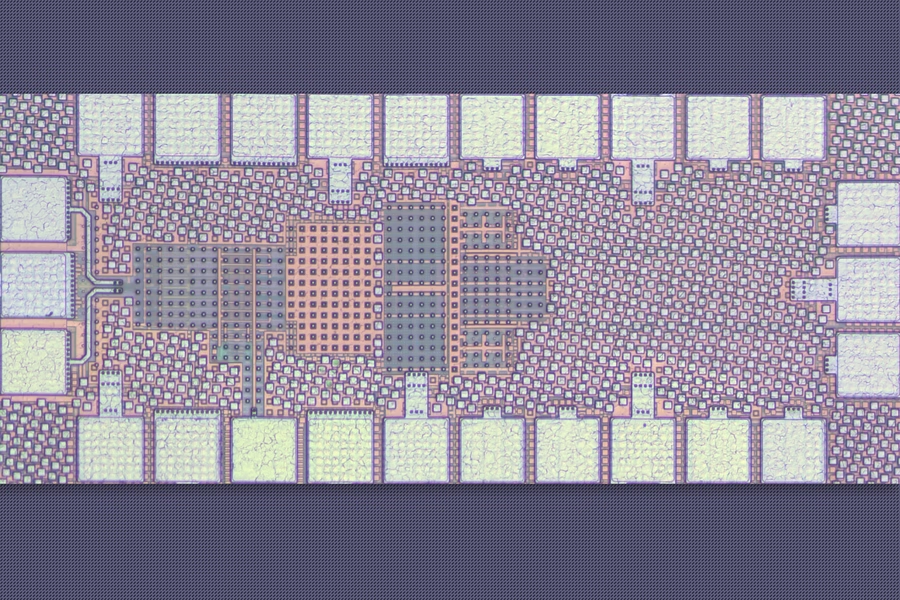

The chip, recently unveiled at the IEEE Radio Frequency Integrated Circuits Symposium, stands out for its novel use of passive filtering and ultra-small capacitors controlled by tiny switches. These switches require far less power than those typically found in existing IoT receivers.

A key innovation lies in the chip’s clever use of a phenomenon called the Miller effect, which allows small capacitors to perform like larger ones. This means the receiver achieves necessary filtering without relying on bulky components, keeping the circuit size under 0.05 square millimeters.

Traditional IoT receivers rely on fixed-frequency filters to block interference, but next-generation 5G-compatible devices need to operate across wider frequency ranges. The MIT design meets this demand using an innovative on-chip switch-capacitor network that blocks unwanted harmonic interference early in the signal chain—before it gets amplified and digitized.

Another critical breakthrough is a technique called bootstrap clocking, which ensures the miniature switches operate correctly even at a low power supply of just 0.6 volts. This helps maintain reliability without adding complex circuitry or draining battery life.

The chip’s minimalist design—using fewer and smaller components—also reduces signal leakage and manufacturing costs, making it well-suited for mass production.

Looking ahead, the MIT team is exploring ways to run the receiver without any dedicated power source—possibly by harvesting ambient energy from nearby Wi-Fi or Bluetooth signals.

The research was conducted by Araei alongside Mohammad Barzgari, Haibo Yang, and senior author Professor Negar Reiskarimian of MIT’s Microsystems Technology Laboratories.

Society

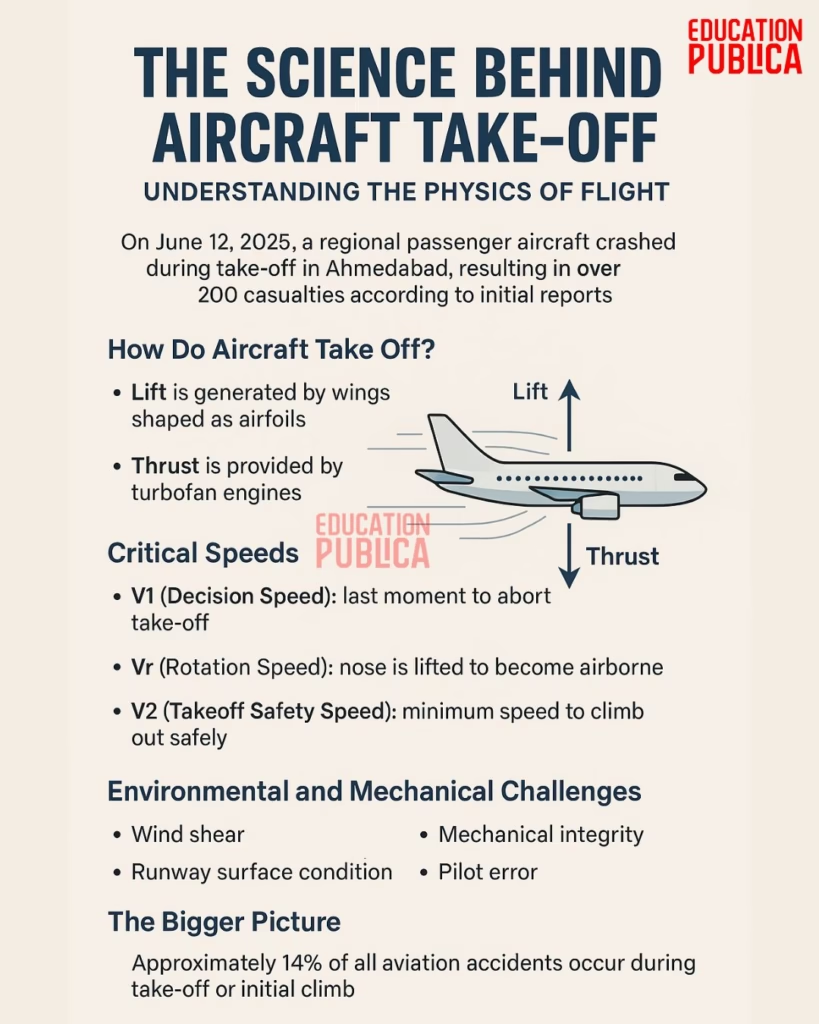

Ahmedabad Plane Crash: The Science Behind Aircraft Take-Off -Understanding the Physics of Flight

Take-off is one of the most critical phases of flight, relying on the precise orchestration of aerodynamics, propulsion, and control systems. Here’s how it works:

On June 12, 2025, a tragic aviation accident struck Ahmedabad, India when a regional passenger aircraft, Air India flight A1-171, crashed during take-off at Sardar Vallabhbhai Patel International Airport. According to preliminary reports, the incident resulted in over 200 confirmed casualties, including both passengers and crew members, and several others are critically injured. The aviation community and scientific world now turn their eyes not just toward the cause but also toward understanding the complex science behind what should have been a routine take-off.

How Do Aircraft Take Off?

Take-off is one of the most critical phases of flight, relying on the precise orchestration of aerodynamics, propulsion, and control systems. Here’s how it works:

1. Lift and Thrust

To leave the ground, an aircraft must generate lift, a force that counters gravity. This is achieved through the unique shape of the wing, called an airfoil, which creates a pressure difference — higher pressure under the wing and lower pressure above — according to Bernoulli’s Principle and Newton’s Third Law.

Simultaneously, engines provide thrust, propelling the aircraft forward. Most commercial jets use turbofan engines, which accelerate air through turbines to generate power.

2. Critical Speeds

Before takeoff, pilots calculate critical speeds:

- V1 (Decision Speed): The last moment a takeoff can be safely aborted.

- Vr (Rotation Speed): The speed at which the pilot begins to lift the nose.

- V2 (Takeoff Safety Speed): The speed needed to climb safely even if one engine fails.

If anything disrupts this process — like bird strikes, engine failure, or runway obstructions — the results can be catastrophic.

Environmental and Mechanical Challenges

Factors like wind shear, runway surface condition, mechanical integrity, or pilot error can interfere with safe take-off. Investigators will be analyzing these very aspects in the Ahmedabad case.

The Bigger Picture

Take-off accounts for a small fraction of total flight time but is disproportionately associated with accidents — approximately 14% of all aviation accidents occur during take-off or initial climb.

Space & Physics

MIT claims breakthrough in simulating physics of squishy, elastic materials

In a series of experiments, the new solver demonstrated its ability to simulate a diverse array of elastic behaviors, ranging from bouncing geometric shapes to soft, squishy characters

Researchers at MIT claim to have unveiled a novel physics-based simulation method that significantly improves stability and accuracy when modeling elastic materials — a key development for industries spanning animation, engineering, and digital fabrication.

In a series of experiments, the new solver demonstrated its ability to simulate a diverse array of elastic behaviors, ranging from bouncing geometric shapes to soft, squishy characters. Crucially, it maintained important physical properties and remained stable over long periods of time — an area where many existing methods falter.

Other simulation techniques frequently struggled in tests: some became unstable and caused erratic behavior, while others introduced excessive damping that distorted the motion. In contrast, the new method preserved elasticity without compromising reliability.

“Because our method demonstrates more stability, it can give animators more reliability and confidence when simulating anything elastic, whether it’s something from the real world or even something completely imaginary,” Leticia Mattos Da Silva, a graduate student at MIT’s Department of Electrical Engineering and Computer Science, said in a media statement.

Their study, though not yet peer-reviewed or published, will be presented at the August proceedings of the SIGGRAPH conference in Vancouver, Canada.

While the solver does not prioritize speed as aggressively as some tools, it avoids the accuracy and robustness trade-offs often associated with faster methods. It also sidesteps the complexity of nonlinear solvers, which are commonly used in physics-based approaches but are often sensitive and prone to failure.

Looking ahead, the research team aims to reduce computational costs and broaden the solver’s applications. One promising direction is in engineering and fabrication, where accurate elastic simulations could enhance the design of real-world products such as garments, medical devices, and toys.

“We were able to revive an old class of integrators in our work. My guess is there are other examples where researchers can revisit a problem to find a hidden convexity structure that could offer a lot of advantages,” Mattos Da Silva added.

The study opens new possibilities not only for digital content creation but also for practical design fields that rely on predictive simulations of flexible materials.

-

Society4 months ago

Society4 months agoStarliner crew challenge rhetoric, says they were never “stranded”

-

Space & Physics3 months ago

Space & Physics3 months agoCould dark energy be a trick played by time?

-

Earth4 months ago

Earth4 months agoHow IIT Kanpur is Paving the Way for a Solar-Powered Future in India’s Energy Transition

-

Space & Physics3 months ago

Space & Physics3 months agoSunita Williams aged less in space due to time dilation

-

Learning & Teaching4 months ago

Learning & Teaching4 months agoCanine Cognitive Abilities: Memory, Intelligence, and Human Interaction

-

Earth2 months ago

Earth2 months ago122 Forests, 3.2 Million Trees: How One Man Built the World’s Largest Miyawaki Forest

-

Women In Science3 months ago

Women In Science3 months agoNeena Gupta: Shaping the Future of Algebraic Geometry

-

Society5 months ago

Society5 months agoSustainable Farming: The Microgreens Model from Kerala, South India