Sustainable Energy

MIT and GE Vernova Launch Energy and Climate Alliance

This collaboration marks the beginning of a five-year partnership between MIT and GE Vernova, a global energy company that emerged from General Electric’s energy division in 2024

MIT and GE Vernova have announced the formation of the MIT-GE Vernova Energy and Climate Alliance, an initiative aimed at advancing sustainable energy systems globally. This collaboration marks the beginning of a five-year partnership between MIT and GE Vernova, a global energy company that emerged from General Electric’s energy division in 2024.

The alliance will promote research, education, and career opportunities for students, faculty, and staff across MIT’s five schools and the MIT Schwarzman College of Computing. Its focus will be on three key areas: decarbonization, electrification, and accelerating renewable energy adoption.

“This alliance will provide MIT students and researchers with a tremendous opportunity to work on energy solutions that could have real-world impact,” said Anantha Chandrakasan, MIT’s chief innovation and strategy officer and dean of the School of Engineering. “GE Vernova brings domain knowledge and expertise deploying these at scale. When our researchers develop new innovative technologies, GE Vernova is strongly positioned to bring them to global markets.”

As part of this collaboration, GE Vernova will sponsor various research projects at MIT and offer philanthropic support for research fellowships. The company is also set to engage with the MIT community through corporate membership programs and professional education initiatives.

“It’s a privilege to combine forces with MIT’s world-class faculty and students as we work together to realize an optimistic, innovation-driven approach to solving the world’s most pressing challenges,” stated Scott Strazik, CEO of GE Vernova. “Through this alliance, we are proud to help drive new technologies while inspiring future leaders to play a meaningful role in deploying technology to improve the planet at companies like GE Vernova.”

“This alliance embodies the spirit of the MIT Climate Project – combining cutting-edge research, a shared drive to tackle today’s toughest energy challenges, and a deep sense of optimism about what we can achieve together,” said MIT President Sally Kornbluth. “With the combined strengths of MIT and GE Vernova, we have a unique opportunity to make transformative progress in electrification, decarbonization, and renewables acceleration.”

The alliance, backed by a $50 million commitment, will operate through MIT’s Office of Innovation and Strategy, funding approximately 12 annual research projects and three master’s student projects in the Technology and Policy Program. These initiatives aim to tackle challenges such as clean energy development, storage solutions, and robust system architectures to support sustainable energy sources.

A joint steering committee from MIT and GE Vernova will select the projects based on an annual call for proposals.

In addition, the alliance will establish around eight endowed GE Vernova research fellowships for MIT students and offer 10 internships that provide hands-on experience across GE Vernova’s global operations. The partnership will also enhance professional education programming for GE Vernova employees and support initiatives within MIT’s Human Insight Collaborative (MITHIC).

“The internships and fellowships will be designed to bring students into our ecosystem,” remarked Roger Martella, Chief Corporate Affairs Officer at GE Vernova. “Students will walk our factory floor, come to our labs, be a part of our management teams, and see how we operate as business leaders. They’ll gain insights into how their classroom learning applies in the real world.”

GE Vernova plans to join several MIT consortia and membership programs, fostering collaboration between industry experts and academic researchers.

With operations in over 100 countries, GE Vernova is committed to designing, manufacturing, and servicing technologies that generate, transfer, and store electricity, all with the goal of decarbonizing the world. Its headquarters in Kendall Square, near MIT, is a strategic advantage for this partnership.

“We’re really good at taking proven technologies and commercializing them and scaling them up through our labs,” Martella said. “MIT excels at generating innovative ideas that shape the future. This partnership is a perfect fit, driven by our shared commitment to research, innovation, and technology.”

The MIT-GE Vernova alliance is the latest addition to MIT’s expanding portfolio of initiatives focused on sustainable energy systems, complementing the ongoing MIT Climate Project, which seeks to address critical challenges in global climate response.

Sustainable Energy

Gujarat, Kerala Top India’s Rooftop Solar Race as PMSGY Expands, Yet Financial Bottlenecks Linger

India’s rooftop solar mission is gaining pace under PMSGY, led by Gujarat and Kerala. Yet, limited financing access and supply chain gaps continue to test its momentum

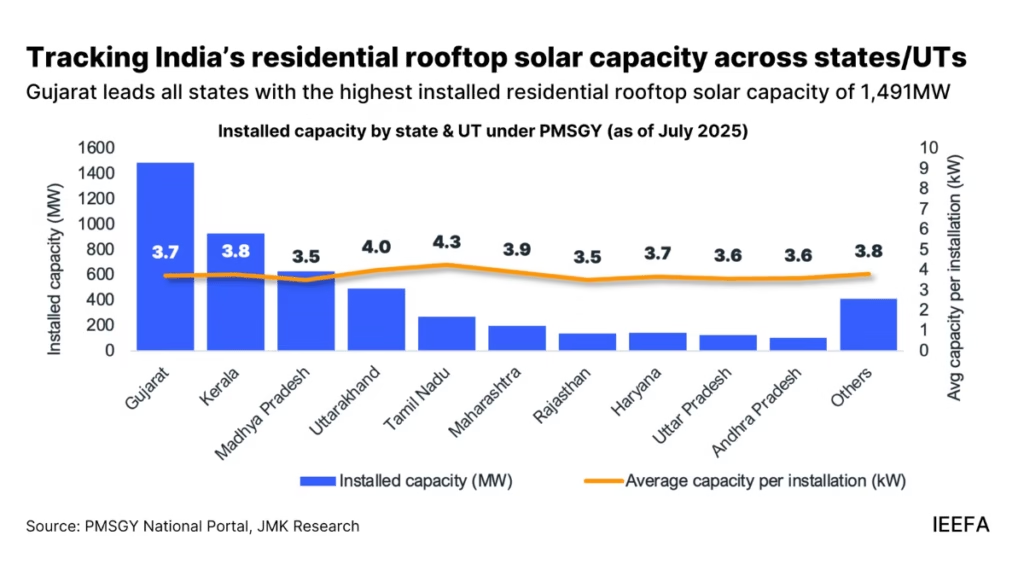

India’s flagship Pradhan Mantri Surya Ghar Yojana (PMSGY) has given a major push to the country’s residential rooftop solar (RTS) sector, adding nearly 4.9 gigawatts (GW) of new capacity in just over a year since its launch. Yet, according to a new report by the Institute for Energy Economics and Financial Analysis (IEEFA) and JMK Research & Analytics, challenges in financing, supply chains, and consumer awareness continue to slow progress toward national targets.

The report, Advancing Residential Rooftop Solar Adoption in India under PM Surya Ghar Yojana, notes that as of July 2025, over 57.9 lakh households have applied for rooftop solar systems under the scheme. Despite this surge — a fourfold rise in applications since March 2024 — only 22.7% have translated into actual installations.

“PMSGY has steadily expanded its policy framework to speed up residential rooftop solar adoption. Since 2024, it has rolled out a nationwide capacity-building programme to train over three lakh people and help vendors, utilities and financiers upskill,” says, Jyoti Gulia, Founder, JMK Research.

Gujarat, Kerala Lead the Way

Gujarat has emerged as the clear front-runner, boasting 1,491 MW of installed residential rooftop capacity — the highest in the country. Maharashtra, Uttar Pradesh, Kerala, and Rajasthan follow, together accounting for more than 77% of total installations under the programme.

These states’ success is credited to their mature solar ecosystems, strong vendor bases, and high consumer awareness. Gujarat and Kerala, for instance, have achieved conversion ratios of over 65%, far above the national average.

However, Kerala’s success has been uneven. As highlighted in an EdPublica investigation — Why Kerala Has Struggled to Replicate Perinjanam’s Solar Success — the state’s progress has been shaped by strong community-led models like Perinjanam’s solar initiative, but replication across districts has faced institutional and financial hurdles. Local leadership and decentralised governance, experts argue, remain key to scaling up such success stories statewide.

Financing, Awareness, and Supply Chain Barriers

Despite the scheme’s momentum, several bottlenecks remain. The report highlights that low consumer awareness of financing options, complicated loan procedures, and technical glitches in the grievance redressal system hinder wider adoption.

“However, low consumer awareness and access to finance remain significant barriers to the adoption of rooftop solar. Outdated perceptions of high upfront costs and maintenance persist, especially in rural areas,” says Prabhakar Sharma, Senior Consultant, JMK Research.

Fragmented supply chains for critical components such as solar panels, inverters, and mounting structures have also caused project delays.

“Establishing clear, time-bound rooftop solar capacity targets at the state level is essential for creating a coherent vision and ensuring effective policy execution,” Vibhuti Garg, Director, IEEFA – South Asia, points out.

Need for Stronger Local Implementation

The report notes that although a grievance redressal mechanism has been set up under PMSGY, its effectiveness remains limited. “PMSGY should establish a district-level escalation matrix so that subsidy disbursement delays, incorrect data entries or portal malfunctions can be routed beyond the DISCOM or portal level,” Aman Gupta, Research Associate, JMK Research says.

Analysts recommend creating state and district facilitation cells to guide consumers through the application and subsidy process, along with extensive public awareness campaigns to educate households about long-term savings from rooftop solar.

Standardisation and Plug-and-Play Solutions

The report stresses the need for standardised rooftop solar kits that integrate panels, inverters, and cables into ready-to-install packages.

“The rooftop solar market continues to face fragmented quality and weak end-to-end guarantees, challenges that standardised plug-and-play solutions can resolve,” Prabhakar Sharma adds.

Promoting the commoditisation of rooftop systems, the authors argue, can help speed up installations and minimise delays.

Beyond Subsidies: Building a Solar-Ready Ecosystem

While the central government has disbursed over INR 9,280 crore (US$1.05 billion) in subsidies so far — just 14% of the total allocated under PMSGY — experts caution that subsidies alone won’t ensure success.

“The long-term success of PMSGY hinges not only on the provision of subsidies but also on its ability to institutionalise streamlined digital processes, standardised product solutions, and consumer-centric support systems,” according to the Report authors’ conclusion.

To meet the ambitious 30GW rooftop solar target by FY2027, India will need to bridge the financing gap, build local capacity, and simplify consumer experiences — transforming rooftops across urban and rural India into decentralised clean energy generators.

Sustainable Energy

MIT Engineers’ Discovery Could Supercharge Hydrogen Economy

MIT engineers create a high-temperature stable palladium membrane, a breakthrough that could revolutionize clean hydrogen production

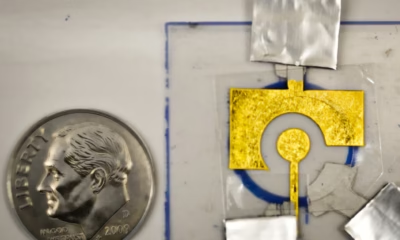

In a leap forward for hydrogen technology, engineers at the Massachusetts Institute of Technology (MIT) have developed a new palladium membrane that remains stable and efficient even at high temperatures, paving the way for cleaner, large-scale hydrogen production. This innovation could help unlock the full potential of a hydrogen-based energy economy by overcoming durability limits that have restricted palladium membranes in the past.

Palladium, a silvery metal, is prized for letting hydrogen pass while blocking all other gases, making it invaluable in filtering and generating pure hydrogen for industries like semiconductor manufacturing, food processing, and fertilizer production. Traditional palladium membranes, however, degrade if exposed to temperatures above about 800 kelvins, restricting their usefulness in high-temperature hydrogen-generating processes.

The new solution from MIT replaces the vulnerable continuous films with a design where palladium is deposited as “plugs” in the pores of a supporting material(see the generated image above). These snug-fitting plugs stay stable and continue separating hydrogen at high temperatures—unlocking opportunities for hydrogen-fuel technologies like compact steam methane reforming and ammonia cracking, which demand resilient membranes for zero-carbon fuel and energy.

“With further work on scaling and validating performance under realistic industrial feeds, the design could represent a promising route toward practical membranes for high-temperature hydrogen production,” said Lohyun Kim PhD ’24 in a media statement

Society

The Dragon and the Elephant Dance for a Cleaner World

New reports from the IEA and Ember show that China and India are leading a global turning point — where renewables now outpace fossil fuels.

In late September, EdPublica reported an inspirational story from Perinjanam, a quiet coastal village in the South Indian state Kerala, where rooftops gleam with solar panels and homes have turned into micro power plants. It was a story of how ordinary citizens, through community effort and government support, took part in a just energy transition.

That local story, seemingly small, was in fact a mirror of a far bigger movement unfolding worldwide. Now, two major global reports–one from the International Energy Agency (IEA) and another from the independent think tank Ember–confirm that the world is entering a decisive new phase in its energy transformation. Together, their findings show that 2025 is shaping up to be the turning point year: the moment when renewables not only surpassed coal but began meeting all new global electricity demand. The year will likely be remembered as the moment when the global energy transition stopped being a promise and became a measurable reality — led by the two Asian giants, China and India.

The Global Picture: IEA’s Big Forecast

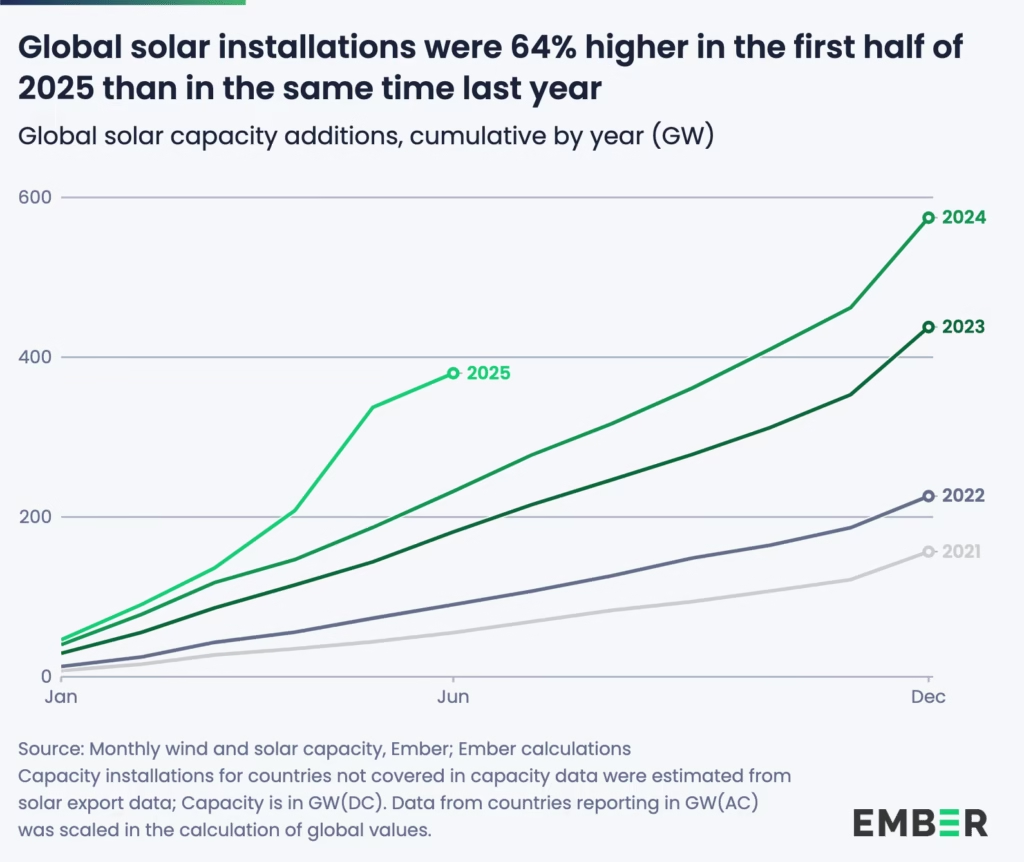

‘The IEA’s Renewables 2025’ report, released on October 7, paints an extraordinary picture of growth and possibility. Despite global headwinds — including high interest rates, supply chain bottlenecks, and policy shifts — renewable energy capacity is projected to more than double by 2030, adding 4,600 gigawatts (GW) of new renewable power.

To grasp that number: it’s equivalent to building the entire current electricity generation capacity of China, the European Union, and Japan combined.

At the centre of this boom is solar photovoltaic (PV) technology, which will account for around 80% of the total growth. The IEA calls solar “the backbone of the energy transition,” driven by falling costs, faster permitting processes, and widespread adoption across emerging economies. Wind, hydropower, bioenergy, and geothermal follow closely behind, expanding capacity even as global systems adapt to higher shares of variable power.

“The growth in global renewable capacity in the coming years will be dominated by solar PV – but with wind, hydropower, bioenergy and geothermal all contributing, too,” said Fatih Birol, Executive Director of the IEA. “As renewables’ role in electricity systems rises in many countries, policymakers need to play close attention to supply chain security and grid integration challenges.”

The IEA forecasts particularly rapid progress in emerging markets. India is set to become the second-largest renewables growth market in the world, after China, reaching its ambitious 2030 targets comfortably. The report highlights new policy instruments — such as auction programs and rooftop solar incentives — that are spurring confidence across Asia, the Middle East, and Africa.

In India, the expansion of corporate power purchase agreements, utility contracts, and merchant renewable plants is also driving a quiet revolution, accounting for nearly 30% of global renewable capacity expansion to 2030.

At the same time, challenges remain. The IEA points to a worrying concentration of solar PV manufacturing in China, where over 90% of supply chain capacity for key components like polysilicon and rare earth materials is expected to remain by 2030.

Grid integration is another bottleneck. As solar and wind grow, many countries are already facing curtailments — when renewable power cannot be fed into the grid due to overload or mismatch in demand. The IEA stresses the need for urgent investment in transmission infrastructure, storage technologies, and flexible generation to prevent this momentum from being wasted.

Evidence on the Ground

If the IEA’s report is a map of where we’re going, Ember’s Mid-Year Global Electricity Review 2025 shows where we are right now — and the signs are unmistakable.

Ember’s data, covering the first half of 2025, reveals that solar and wind met all of the world’s rising electricity demand — and even caused a slight decline in fossil fuel generation. It’s a first in recorded history.

“We are seeing the first signs of a crucial turning point,” said Małgorzata Wiatros-Motyka, Senior Electricity Analyst at Ember. “Solar and wind are now growing fast enough to meet the world’s growing appetite for electricity. This marks the beginning of a shift where clean power is keeping pace with demand growth.”

Global electricity demand rose by 2.6% in early 2025, adding about 369 terawatt-hours (TWh) compared with the same period last year. Solar alone met 83% of that rise, thanks to record generation growth of 306 TWh, a year-on-year increase of 31%. Wind contributed another 97 TWh, leading to a net decline in both coal and gas generation.

Coal generation fell 0.6% (-31 TWh) and gas 0.2% (-6 TWh), marking a combined fossil decline of 0.3% (-27 TWh). As a result, global power sector emissions fell by 0.2%, even as demand continued to grow.

Most significantly, for the first time ever, renewables generated more power than coal. Renewables supplied 5,072 TWh, overtaking coal’s 4,896 TWh — a symbolic but historic milestone.

“Solar and wind are no longer marginal technologies — they are driving the global power system forward,” said Sonia Dunlop, CEO of the Global Solar Council. “The fact that renewables have overtaken coal for the first time marks a historic shift.”

China and India Lead the Way

The two reports together highlight that the epicenter of the clean energy shift is now in Asia.

According to Ember, China’s fossil generation fell by 2% (-58.7 TWh) in the first half of 2025, as clean power growth outpaced rising electricity demand. Solar generation jumped 43% (+168 TWh), and wind grew 16% (+79 TWh), together helping cut the country’s power sector emissions by 1.7% (-47 MtCO₂).

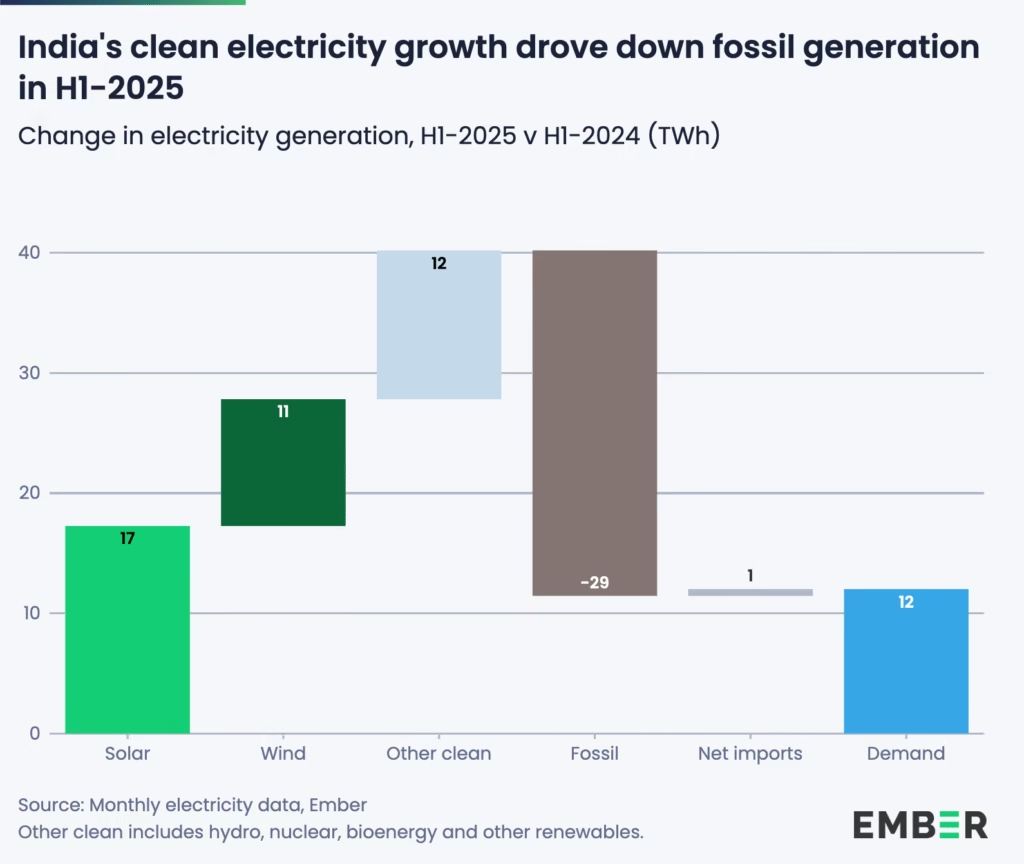

Meanwhile, India’s fossil fuel decline was even steeper in relative terms. Solar and wind generation grew at record pace — solar by 25% (+17 TWh) and wind by 29% (+11 TWh) — while electricity demand rose only 1.3%, far slower than in 2024. The result: coal use dropped 3.1% (-22 TWh) and gas by 34% (-7 TWh), leading to an estimated 3.6% fall in power sector emissions.

For both countries, these numbers align closely with the IEA’s projections. Together, China and India are now the primary engines of renewable capacity growth, demonstrating how large emerging economies can pivot toward clean energy while maintaining development momentum.

Setbacks Elsewhere

Yet progress is uneven. In the United States and European Union, fossil generation actually rose in early 2025.

In the U.S., a 3.6% rise in demand outpaced clean power additions, leading to a 17% increase in coal generation (+51 TWh), though gas use fell slightly. The EU also saw higher gas and coal use due to weaker wind and hydro output.

The IEA attributes part of this slowdown to policy uncertainty, especially in the U.S., where an early phase-out of federal tax incentives has reduced renewable growth expectations by almost 50% compared to last year’s forecast. Europe’s problem is different — a mature but strained grid facing seasonal fluctuations and low wind output.

These regional discrepancies underscore the IEA’s core message: achieving a clean power future isn’t just about building more solar farms, but about building smarter systems — integrated, flexible, and resilient.

Beyond Power

Both reports agree that while renewables are transforming electricity, their impact on transport and heating remains limited.

In transport, the IEA projects renewables’ share to rise modestly from 4% today to 6% in 2030, mostly through electric vehicles and biofuels. In heating, renewables are set to grow from 14% to 18% of global energy use over the same period.

These slower-moving sectors will define the next frontier of decarbonization — one where electrification, hydrogen, and new thermal storage technologies must play a greater role.

The Big Picture

Put together, the IEA’s forecasts and Ember’s real-world data signal that the clean energy transition has passed the point of no return.

Solar and wind are no longer simply catching up — they are now shaping global power dynamics. Their continued expansion is not only meeting new demand but beginning to displace fossil fuels outright.

“As costs of technologies continue to fall, now is the perfect moment to embrace the economic, social and health benefits that come with increased solar, wind and batteries,” said Ember’s Wiatros-Motyka.

Yet both agencies caution: to sustain this momentum, governments must expand grid capacity, diversify supply chains, and improve energy storage systems. Without these, the 2025 breakthrough could become a bottleneck.

A Symbol and a Signal

In a way, the world in 2025 looks a lot like Perinjanam did a few years ago — a place where optimism met obstacles, but the light won. What was once a village-scale transition is now a planetary transformation, proving that even small local models can foreshadow global change.

From Kerala’s rooftops to China’s vast solar parks, from India’s wind corridors to Africa’s mini-grids, the direction is unmistakable: the sun and wind are powering the next phase of human progress.

If 2024 was the year of warnings, 2025 is the year of evidence. The global energy system is finally tilting toward sustainability — not someday, but today.

-

Space & Physics5 months ago

Space & Physics5 months agoIs Time Travel Possible? Exploring the Science Behind the Concept

-

Know The Scientist5 months ago

Know The Scientist5 months agoNarlikar – the rare Indian scientist who penned short stories

-

Society4 months ago

Society4 months agoShukla is now India’s first astronaut in decades to visit outer space

-

Earth5 months ago

Earth5 months agoWorld Environment Day 2025: “Beating plastic pollution”

-

Society5 months ago

Society5 months agoAxiom-4 will see an Indian astronaut depart for outer space after 41 years

-

Society6 months ago

Society6 months agoRabies, Bites, and Policy Gaps: One Woman’s Humane Fight for Kerala’s Stray Dogs

-

The Sciences4 months ago

The Sciences4 months agoHow a Human-Inspired Algorithm Is Revolutionizing Machine Repair Models in the Wake of Global Disruptions

-

Space & Physics3 months ago

Space & Physics3 months agoJoint NASA-ISRO radar satellite is the most powerful built to date