Sustainable Energy

Soda cans can split seawater sustainably to free up green hydrogen

Engineers at MIT use seawater in addition to recycled aluminum from soda cans, to produce low-carbon hydrogen at scale.

Engineers at MIT have unveiled a potentially game-changing method to produce hydrogen that could drastically reduce the carbon footprint associated with the fuel’s production — a critical step in realizing hydrogen’s promise as a clean energy solution.

Their research, published in the peer-reviewed journal, Cell Reports Sustainability, combines seawater, recycled aluminum from soda cans, and a rare-metal alloy to generate hydrogen with a significantly lower environmental impact.

A full life-cycle analysis by the research team shows the process emits just 1.45 kilograms of carbon dioxide per kilogram of hydrogen produced — a dramatic drop from the 11 kilograms typically emitted by fossil-fuel-based methods.

“This work highlights aluminum’s potential as a clean energy source and offers a scalable pathway for low-emission hydrogen deployment in transportation and remote energy systems,” Aly Kombargi, the paper’s lead author said in a media statement.

A mechanical engineer, Dr. Kombargi had received their doctoral degree fairly recently. Their fellow coauthors include MIT researchers, Brooke Bao and Enoch Ellis. Whereas Douglas Hart, the professor in mechanical engineering, was cited as senior author.

A Clean Cycle

The MIT team first made headlines last year when they demonstrated a lab-scale reaction that turned seawater and aluminum treated with gallium-indium into hydrogen gas. The novelty lies in how the alloy strips aluminum of its protective oxide layer, allowing it to react with water and produce pure hydrogen. Crucially, the salt in seawater helps the gallium-indium alloy to precipitate out and be reused, adding to the process’s sustainability.

To evaluate its real-world viability, the researchers conducted a cradle-to-grave analysis of the process — from sourcing recycled aluminum to transporting the resulting hydrogen. They used Earthster, a life-cycle assessment platform, to calculate emissions and economic costs across various scenarios.

Their lowest-emission scenario relies on secondary (recycled) aluminum and readily available seawater, producing hydrogen at around $9 per kilogram — a price that matches other emerging green hydrogen technologies powered by solar or wind.

A New Model for Hydrogen Infrastructure

Unlike traditional hydrogen production, which requires complex storage and transport infrastructure, the MIT method could simplify the supply chain.

In the envisioned commercial model, aluminum pellets treated with gallium-indium would be transported — rather than the hydrogen itself — to fueling stations near coastal areas. There, the pellets would be combined with seawater to generate hydrogen on demand.

This approach not only sidesteps the risks of transporting volatile hydrogen gas, but also produces a potentially valuable byproduct: boehmite, an aluminum-based mineral used in semiconductors and industrial materials. Selling this byproduct could further reduce production costs.

“There are a lot of things to consider,” Kombargi noted, “but the process works — which is the most exciting part. And we show that it can be environmentally sustainable.”

Electric Bikes and Beyond

The team has already created a prototype reactor, about the size of a water bottle, capable of generating enough hydrogen to power an electric bike for hours. They have also demonstrated the system’s capacity to fuel a small car and are exploring underwater applications, including powering boats or autonomous submersibles using surrounding seawater.

As nations race to decarbonize energy systems, this MIT breakthrough points to a novel, scalable solution — one that turns common materials into a clean fuel source and may help bridge the gap to a hydrogen-powered future.

Sustainable Energy

Can ammonia power a low-carbon future? New MIT study maps global costs and emissions

Under what conditions can ammonia truly become a low-carbon energy solution? MIT researchers attempt to resolve this

Ammonia, long known as the backbone of global fertiliser production, is increasingly being examined as a potential pillar of the clean energy transition. Energy-dense, carbon-free at the point of use, and already traded globally at scale, ammonia is emerging as a candidate fuel and a carrier of hydrogen. But its climate promise comes with a contradiction: today’s dominant method of producing ammonia carries a heavy carbon footprint.

A new study by researchers from the MIT Energy Initiative (MITEI) attempts to resolve this tension by answering a foundational question for policymakers and industry alike: under what conditions can ammonia truly become a low-carbon energy solution?

A global view of ammonia’s future

In a paper published in Energy and Environmental Science, the researchers present the largest harmonised dataset to date on the economic and environmental impacts of global ammonia supply chains. The analysis spans 63 countries and evaluates multiple production pathways, trade routes, and energy inputs, offering a comprehensive view of how ammonia could be produced, shipped, and used in a decarbonising world.

“This is the most comprehensive work on the global ammonia landscape,” says senior author Guiyan Zang, a research scientist at MITEI. “We developed many of these frameworks at MIT to be able to make better cost-benefit analyses. Hydrogen and ammonia are the only two types of fuel with no carbon at scale. If we want to use fuel to generate power and heat, but not release carbon, hydrogen and ammonia are the only options, and ammonia is easier to transport and lower-cost.”

Why data matters

Until now, assessments of ammonia’s climate potential have been fragmented. Individual studies often focused on single regions, isolated technologies, or only cost or emissions, making global comparisons difficult.

“Before this, there were no harmonized datasets quantifying the impacts of this transition,” says lead author Woojae Shin, a postdoctoral researcher at MITEI. “Everyone is talking about ammonia as a super important hydrogen carrier in the future, and also ammonia can be directly used in power generation or fertilizer and other industrial uses. But we needed this dataset. It’s filling a major knowledge gap.”

To build the database, the team synthesised results from dozens of prior studies and applied common frameworks to calculate full lifecycle emissions and costs. These calculations included feedstock extraction, production, storage, shipping, and import processing, alongside country-specific factors such as electricity prices, natural gas costs, financing conditions, and energy mix.

Comparing production pathways

Today, most ammonia is produced using the Haber–Bosch process powered by fossil fuels, commonly referred to as “grey ammonia.” In 2020, this process accounted for about 1.8 percent of global greenhouse gas emissions. While economically attractive, it is also the most carbon-intensive option.

The study finds that conventional grey ammonia produced via steam methane reforming (SMR) remains the cheapest option in the U.S. context, at around 48 cents per kilogram. However, it also carries the highest emissions, at 2.46 kilograms of CO₂ equivalent per kilogram of ammonia.

Cleaner alternatives offer substantial emissions reductions at higher cost. Pairing SMR with carbon capture and storage cuts emissions by about 61 percent, with a 29 percent cost increase. A full global shift to ammonia produced with conventional methods plus carbon capture could reduce global greenhouse gas emissions by nearly 71 percent, while raising costs by 23.2 percent.

More advanced “blue ammonia” pathways, such as auto-thermal reforming (ATR) with carbon capture, deliver deeper emissions cuts at relatively modest cost increases. One ATR configuration achieved emissions of 0.75 kilograms of CO₂ equivalent per kilogram of ammonia, at roughly 10 percent higher cost than conventional SMR.

At the far end of the spectrum, “green ammonia” produced using renewable electricity can reduce emissions by as much as 99.7 percent, but at a significantly higher cost—around 46 percent more than today’s baseline. Ammonia produced using nuclear electricity showed near-zero emissions in the analysis.

Geography matters

The study also reveals that the viability of low-carbon ammonia depends heavily on geography. Countries with abundant, low-cost natural gas are better positioned to produce blue ammonia competitively, while regions with cheap renewable electricity are more favourable for green ammonia.

China emerged as a potential future supplier of green ammonia to multiple regions, while parts of the Middle East showed strong competitiveness in low-carbon ammonia production. In contrast, ammonia produced using carbon-intensive grid electricity was often both more expensive and more polluting than conventional methods.

From research to policy

Interest in low-carbon ammonia is no longer theoretical. Countries such as Japan and South Korea have incorporated ammonia into national energy strategies, including pilot projects using ammonia for power generation and financial incentives tied to verified emissions reductions.

“Ammonia researchers, producers, as well as government officials require this data to understand the impact of different technologies and global supply corridors,” Shin says.

Zang adds that the dataset is designed not just as an academic exercise, but as a decision-making tool. “We collaborate with companies, and they need to know the full costs and lifecycle emissions associated with different options. Governments can also use this to compare options and set future policies. Any country producing ammonia needs to know which countries they can deliver to economically.”

As global demand for low-carbon fuels accelerates toward mid-century, the study suggests that ammonia’s role will depend less on ambition alone, and more on informed choices—grounded in data—about how and where it is produced.

Sustainable Energy

Do Renewables Really Push Up Power Prices? What the Data from the US, Europe and India Actually Shows

An extensive analysis of electricity markets across the United States, the European Union, Australia, and India shows that high penetration of wind and solar is not associated with higher power prices

For more than a decade, a familiar argument has echoed through political speeches and policy debates: wind and solar power are unreliable, require costly backup systems, and ultimately make electricity more expensive. From Washington to Westminster, critics of clean energy have repeatedly framed renewables as an economic burden rather than a solution.

But a growing body of real-world data tells a very different story.

An extensive analysis of electricity markets across the United States, the European Union, Australia, and India shows that high penetration of wind and solar is not associated with higher power prices. “In many cases, it is linked to below-average electricity costs, directly challenging the claim that renewables drive up consumer bills,” according to an analysis, titled The myth of renewables pushing up power prices, by Zero Carbon Analytics.

The claim versus the evidence

Opponents of renewable energy often argue that variable sources like wind and solar require “parallel systems” of fossil-fuel backup, making the overall grid more expensive. This argument has been voiced at the highest levels of politics.

In a September 2025 speech to the United Nations, US President Donald Trump described wind power as the “most expensive energy ever conceived” and said renewables are “unreliable” and “too expensive.” Similar claims have been made in the UK, where Conservative Party leader Kemi Badenoch argued that renewables and decarbonisation policies are “driving up the cost of energy” .

However, when electricity prices are examined alongside generation data, these assertions do not hold up.

“Claims that renewables drive up total costs are unsubstantiated when looking at hard data from numerous markets,” the report notes. In regions leading the transition to wind and solar, end-user electricity prices have “in most cases not climbed any faster than in places still more dependent on fossil fuels”.

Renewables versus fossil fuels: a cost reality check

At the level of generation economics, the advantage of renewables is already clear. According to the International Renewable Energy Agency (IRENA), nine out of ten new grid-scale renewable projects in 2024 produced electricity more cheaply than the cheapest new fossil-fuel alternatives.

Onshore wind now has the lowest average levelised cost of electricity (LCOE) globally at USD 0.034 per kWh, followed by solar photovoltaics at USD 0.043 per kWh. Power from new onshore wind farms is 53% cheaper than the most affordable fossil-fuel-based alternatives, IRENA reports.

Crucially, renewables paired with battery storage are also approaching cost parity with fossil fuel generation in key markets—undermining the argument that intermittency automatically means higher system costs.

The United States: cheaper power where renewables lead

In the world’s largest electricity market, the data is striking. Most US states with above-average shares of wind and solar in their electricity mix also have below-average residential power prices.

In the first nine months of 2025, three states—Iowa, South Dakota and New Mexico—generated more than 50% of their electricity from wind and solar. All three had household electricity prices below the national average. Among the ten US states with the lowest residential electricity tariffs, seven have above-average renewable integration, including Oklahoma, one of the country’s wind power leaders. The few exceptions—Louisiana, Arkansas and Washington—reflect local market dynamics rather than renewable costs.

California and Hawaii are often cited as counter-examples: both have high renewable shares and high electricity prices. But the report stresses that renewables are not the main driver.

In Hawaii, high prices stem largely from reliance on expensive imported petroleum. In California, electricity bills are pushed up by “significant and increasing wildfire-related costs” and grid infrastructure spending, according to the state’s Legislative Analyst’s Office .

Notably, despite these high absolute prices, electricity price inflation in both states has been well below the national average in 2025. While US residential prices rose 4.9% year-on-year, prices in California remained flat even as wind and solar shares increased by 5.8 percentage points. In Hawaii, residential prices fell 6.6% as renewable penetration rose further.

A separate study by Lawrence Berkeley National Laboratory reinforces this picture, finding that US power generation costs declined in real terms between 2019 and 2024, with rising bills driven instead by grid upgrades, supply-chain constraints and climate-related damage—not renewables.

Europe: breaking the link between gas and power prices

In the European Union, where the energy transition is further advanced, the relationship between renewables and prices is even clearer.

Most EU countries with above-average shares of wind and solar have below-average household electricity prices (pre-tax). Denmark, a global leader in variable renewables, exemplifies this trend.

The reason lies in how electricity markets work. In Europe, wholesale prices are set by the most expensive generator needed at any given moment—often fossil gas. In 2022, gas set day-ahead electricity prices around 60% of the time, despite supplying only 20% of electricity, according to the International Energy Agency (IEA).

As wind and solar expand, fossil fuels are needed less often, reducing their ability to dictate prices.

Spain offers a powerful case study. Wind and solar accounted for 44% of Spain’s electricity generation in the first half of 2025, compared to 31.4% across the EU. As a result, fossil fuels set Spanish power prices only 19% of the time, down from 75% in 2019. Spain’s wholesale electricity prices were 32% lower than the EU average during this period.

These savings reached consumers. Spanish households paid an average of EUR 0.18 per kWh, 13.1% below the EU average in early 2025.

The IEA estimates that EU consumers saved around EUR 100 billion between 2021 and 2023 due to new wind and solar replacing expensive fossil fuel generation—and that savings could have been 15% higher with faster deployment.

India: early transition, emerging signals

India’s power system remains dominated by coal, which supplied 73.6% of electricity in 2024, according to Ember. At this stage, the report finds no clear nationwide relationship between renewable penetration and power prices, largely because many states still have negligible wind and solar capacity.

However, early signals are emerging. In Rajasthan, where renewable deployment is more advanced, the average price paid by distribution utilities is below the national median.

A peer-reviewed study in the journal Energy Policy suggests that rising renewable integration in Madhya Pradesh could reduce power purchase costs by up to 11%, with savings increasing as demand grows and technology costs continue to fall.

Australia: complexity, but clear daily signals

Australia presents a more complex picture. In the third quarter of 2025, renewables-laggard Queensland recorded the lowest wholesale prices, while renewables-leader South Australia recorded the highest.

But the report stresses that South Australia’s high prices predate its energy transition, which only accelerated around a decade ago. Structural issues—such as a concentrated market for “on-demand” electricity and limited transmission—play a major role.

Daily data tells a different story. When wind and solar make up a large share of South Australia’s electricity mix, prices tend to fall. On days when renewables exceed 85% of generation, wholesale prices sometimes turn negative, reflecting abundant low-cost supply.

Looking ahead, Australia’s Energy Market Commission expects national residential electricity prices to fall by around 5% by 2030—but warns that prices could rise again if renewable deployment slows.

What the global data really says

Across markets with vastly different political systems, grid structures and fuel dependencies, one pattern is consistent: renewables are not driving up electricity prices.

“There is ample evidence that renewables have shielded consumers from energy price spikes during global crises,” the report points out. With the cost of wind, solar and battery storage continuing to fall, countries have an opportunity to build more resilient, affordable and stable electricity systems—provided supportive policy frameworks are in place

The myth that renewables make power expensive persists in political rhetoric. The data, however, tells a quieter but far more compelling story—one where clean energy increasingly acts as a buffer against volatility, rather than its cause.

Sustainable Energy

The $76/MWh Breakthrough: Battery-Backed Solar Becomes the Cheapest Firm Power

The battery price collapse that just made solar a 24/7 power source. Utility-scale battery storage is now cheap enough to make dispatchable solar power economically viable in markets outside China and the US.

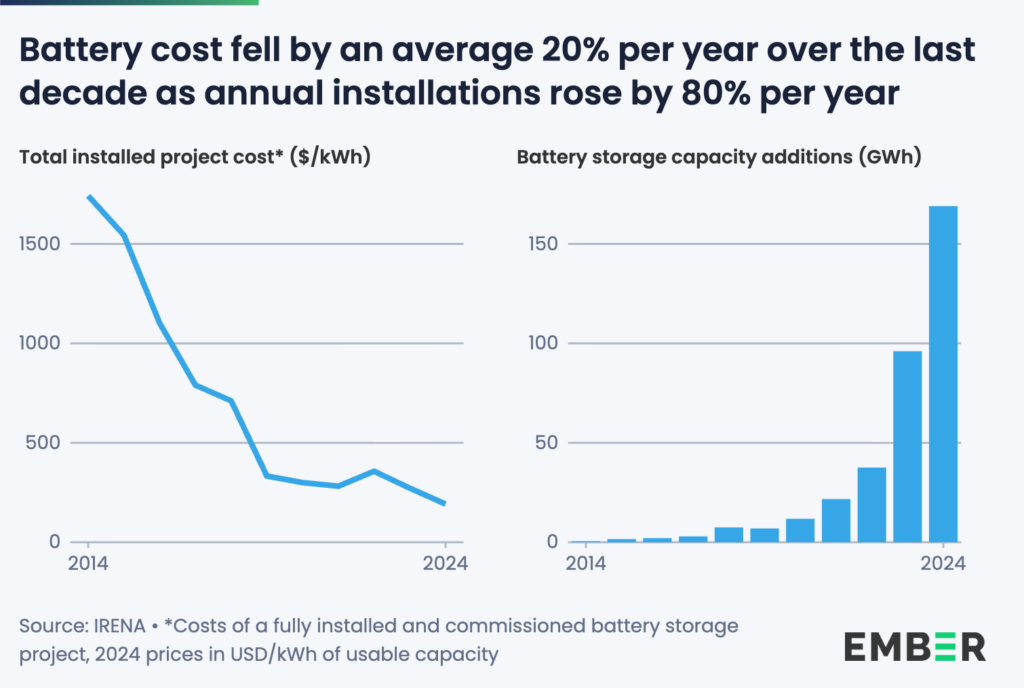

For years, clean-energy advocates spoke about a coming inflection point — a moment when renewable energy would stop being intermittent and start behaving like the dependable backbone of a modern grid. Has that moment quietly arrived? And it didn’t come from a single breakthrough technology, but from something more subtle and powerful: a sudden, cascading collapse in the cost of utility-scale battery storage.

In just two years, the economics of clean electricity have undergone one of the most dramatic shifts since the birth of the solar industry itself. Battery storage systems — long considered the missing link in renewable-dominant grids — have become so inexpensive that they now make solar energy dispatchable, not just abundant.

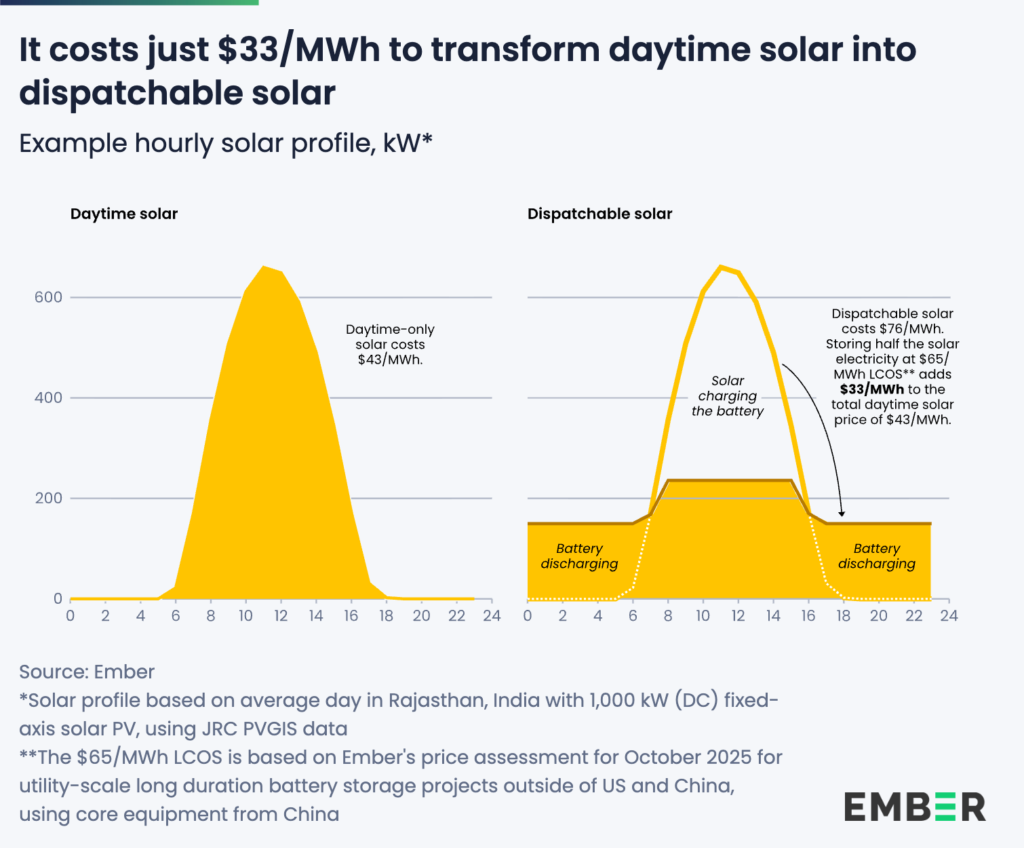

Utility-scale battery storage has crossed a decisive economic threshold in 2025. Fresh data from energy think tank Ember shows that the cost of turning abundant daytime solar power into on-demand, anytime electricity has fallen to $65/MWh, making stored solar competitive with fossil-fuel-based power in many markets.

The shift is not hypothetical. It is real, measurable, and unfolding at extraordinary speed. Across India, Italy, Saudi Arabia, and beyond, a pattern is emerging: utility-scale battery projects clearing auctions at around US$120–125/kWh, with core equipment priced near US$75/kWh, and installation, grid integration, and civil-works accounting for the remainder.

Kostantsa Rangelova, Global Electricity Analyst at Ember, points out the scale of the transformation with unusual bluntness: “After a 40% fall in 2024 in battery equipment costs, it’s clear we’re on track for another major fall in 2025. The economics for batteries are unrecognisable, and the industry is only just getting to grips with this new paradigm.”

The Silent Revolution Inside a Battery

The collapse in cost is only part of the story — the other half is technological maturity. Modern utility-scale batteries now offer:

- 20-year lifetimes

- 10,000–12,000 cycles

- Round-trip efficiency above 90%

This is not incremental improvement. It is structural change.

For decades, the energy world assumed batteries were too fragile, too short-lived, too expensive for grid infrastructure. In 2025, they are emerging as among the most reliable long-duration assets in the power sector — often outliving the fossil-fuel plants they are replacing.

And just beneath the lithium boom lies something even more consequential: the arrival of sodium-ion batteries, which skip the need for lithium, nickel, or cobalt — promising prices once considered impossible.

When Cheap Batteries Meet Cheap Solar

The most important number in all the new data is not the capex, or cycle life, or equipment pricing. It is this:

US$76 per megawatt-hour.

That is the cost of delivering solar electricity whenever it is needed, day or night — if half of solar output is stored in batteries at US$65/MWh and the rest supplied directly during the day. In other words: solar + storage has become a dispatchable baseload resource.

For countries with rising electricity demand, this is seismic.

Rangelova puts it simply: “Solar is no longer just cheap daytime electricity, now it’s anytime dispatchable electricity. This is a game-changer for countries with fast-growing demand and strong solar resources.”

Gas markets — especially those reliant on imported LNG — cannot compete with $76/MWh firm clean power without subsidies or regulatory advantage. Coal plants — once symbols of energy security — now struggle to match either the cost or flexibility of storage-backed solar.

A Lesson from Kerala: Cheap Solar Isn’t Enough Without Storage

Even in regions with abundant solar potential and strong rooftop adoption, intermittency remains a barrier. Take the example of Kerala’s celebrated Perinjanam Energy Project, which electrified hundreds of households through community-driven rooftop solar and inspired nationwide interest.

Despite the early promise, the project — like many others across the state — struggled to scale. Limited land, regulatory uncertainty, low uptake of storage solutions, and weak incentive frameworks meant that daytime solar generation rarely translated into reliable electricity at night. The result: solar remained supplemental, not transformative.

This Kerala story captures a broader truth: solar panels alone don’t solve energy access and reliability problems. Without cost-effective storage, solar output — no matter how abundant — remains tied to the sun. The battery price collapse of 2025 changes that equation entirely, paving the way for renewable energy systems that are not just clean, but dependable.

What Happens Next

The global power system is entering an era in which:

- Solar is the world’s cheapest electricity.

- Batteries are the world’s cheapest way to deliver that electricity when it’s needed.

- And the combination is now cheaper than building most new fossil-fuel plants.

The implications are enormous. Fossil-fuel peakers — long viewed as indispensable for evening demand peaks — are likely to be replaced by four-hour battery systems. Energy planners are questioning whether large gas or coal plants still make sense. Countries with surging power demand are increasingly designing energy systems around solar + storage from the outset.

Cheap batteries, in short, have not just made solar better. They have made solar inevitable.

And as Ember’s analysts conclude in their report: “Cheap batteries do not just complement solar — they unlock its full potential.”

-

Society1 month ago

Society1 month agoThe Ten-Rupee Doctor Who Sparked a Health Revolution in Kerala’s Tribal Highlands

-

COP303 months ago

COP303 months agoBrazil Cuts Emissions by 17% in 2024—Biggest Drop in 16 Years, Yet Paris Target Out of Reach

-

Earth3 months ago

Earth3 months agoData Becomes the New Oil: IEA Says AI Boom Driving Global Power Demand

-

COP303 months ago

COP303 months agoCorporate Capture: Fossil Fuel Lobbyists at COP30 Hit Record High, Outnumbering Delegates from Climate-Vulnerable Nations

-

Society2 months ago

Society2 months agoFrom Qubits to Folk Puppetry: India’s Biggest Quantum Science Communication Conclave Wraps Up in Ahmedabad

-

Women In Science4 months ago

Women In Science4 months agoThe Data Don’t Lie: Women Are Still Missing from Science — But Why?

-

Space & Physics2 months ago

Space & Physics2 months agoIndian Physicists Win 2025 ICTP Prize for Breakthroughs in Quantum Many-Body Physics

-

Health3 months ago

Health3 months agoAir Pollution Claimed 1.7 Million Indian Lives and 9.5% of GDP, Finds The Lancet